With our longstanding history of being at the top of the market we are committed to bringing our customers only the best in quality, service and reliability.

Founded in 1987, Brisar Delvco Industries, Inc., is a leader in turn-key Contract Packaging Solutions. We provide a broad range of in-house services including blister packaging, blister carding, medical device packaging, pouching dietary supplements, OTC drugs, overwrapping, Direct Mail promotional packaging, auto-cartoning, along with other packaging processes. All under one umbrella in a...

At Akers Packaging Service Group, we take pride in delivering comprehensive packaging solutions that go far beyond simply supplying materials. Our strength lies in contract packaging, where we bring together decades of expertise, state-of-the-art facilities, and a dedicated team to manage packaging projects from start to finish.

Based in California, Teamwork Packaging specializes in all aspects of turnkey packaging. We provide innovative packaging solutions in response to the changing needs of the packaging industry. Our custom packaging displays will meet and exceed your specific packaging needs. Some of our services include auto-bagging, cello wrapping, coding, shrink wrapping, sleeve bundling and more. Call us today!

At RCS Empowers, Inc., we take pride in providing high-quality contract packaging services that help our partners streamline production and meet their customers’ needs efficiently. We understand that every packaging project is unique, which is why we offer flexible solutions designed to handle a wide range of products, from consumer goods to industrial materials.

More Blister Packaging Companies

Blister Packaging: The Comprehensive Guide for Product Protection and Presentation

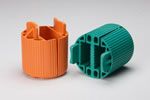

Blister packs are preformed packing materials made up of a malleable lid and a thermoformed plastic cavity. Blister packaging is a specialized form of packaging that is typically used to hold small items, like pills, tablets, capsules, and even consumer goods. Blister packs are produced by applying heat on a sheet of plastic and molding it to form a bubble, which is the “blister” that covers and protects the product inside. This unique packaging solution is widely used across industries for its versatility, cost-effectiveness, and ability to display products clearly while offering robust protection.

The product is then inserted into the blister in this style of packaging. Various varieties of blister packaging exist, depending on the use. They are utilized to package consumer goods such as groceries, electronics, small gadgets, toys, and tools, due to their inexpensive cost, accessible raw ingredients, and quick processing times. In particular, blister packs are most frequently used by the pharmaceutical industry to package medicinal items such as pills, tablets, capsules, and lozenges for both over-the-counter and prescription medications. This packaging method is trusted for its hygienic protection, tamper evidence, and unit-dose delivery.

Blister packs are constructed as push-through blisters, featuring molded plastic containing compartments for individual pills. The push-through closure is made of blister film or lid film and a thin sheet of aluminum foil. The enclosed capsules and tablets are, therefore, hygienically protected and clean from external factors such as moisture, air, and contaminants. They are also lightweight, portable, and simple to handle, making medication adherence easier for patients and caregivers.

What Is Blister Packaging? Key Components and Materials

Blister packaging refers to a system where products are sealed between a pre-formed plastic cavity and a backing material, which can be either a paperboard, aluminum foil, or plastic film. The primary components of blister packaging include:

- Blister cavity: The transparent, molded compartment that holds the product securely in place.

- Lid or backing: Usually made from aluminum foil, paperboard, or a combination of materials, providing product information and tamper evidence.

- Sealing layer: An adhesive or heat-sealed layer that bonds the cavity to the backing, ensuring product integrity.

Primary packaging like blister packs is critical in the pharmaceutical packaging industry, but it is also widely used in retail packaging, food packaging, and even for hardware and batteries. The choice of materials—such as PVC, PVDC, PET, or aluminum—impacts the barrier properties, product shelf life, and recyclability of the final package.

How Blister Packaging is Made

Blister packaging manufacturing is a multi-step process designed to ensure both protection and presentation of the packaged product. The process includes the following key stages:

1. Blister Forming

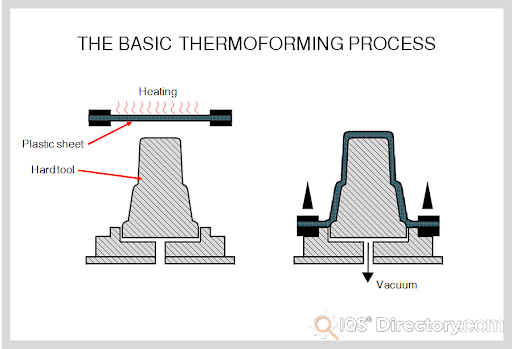

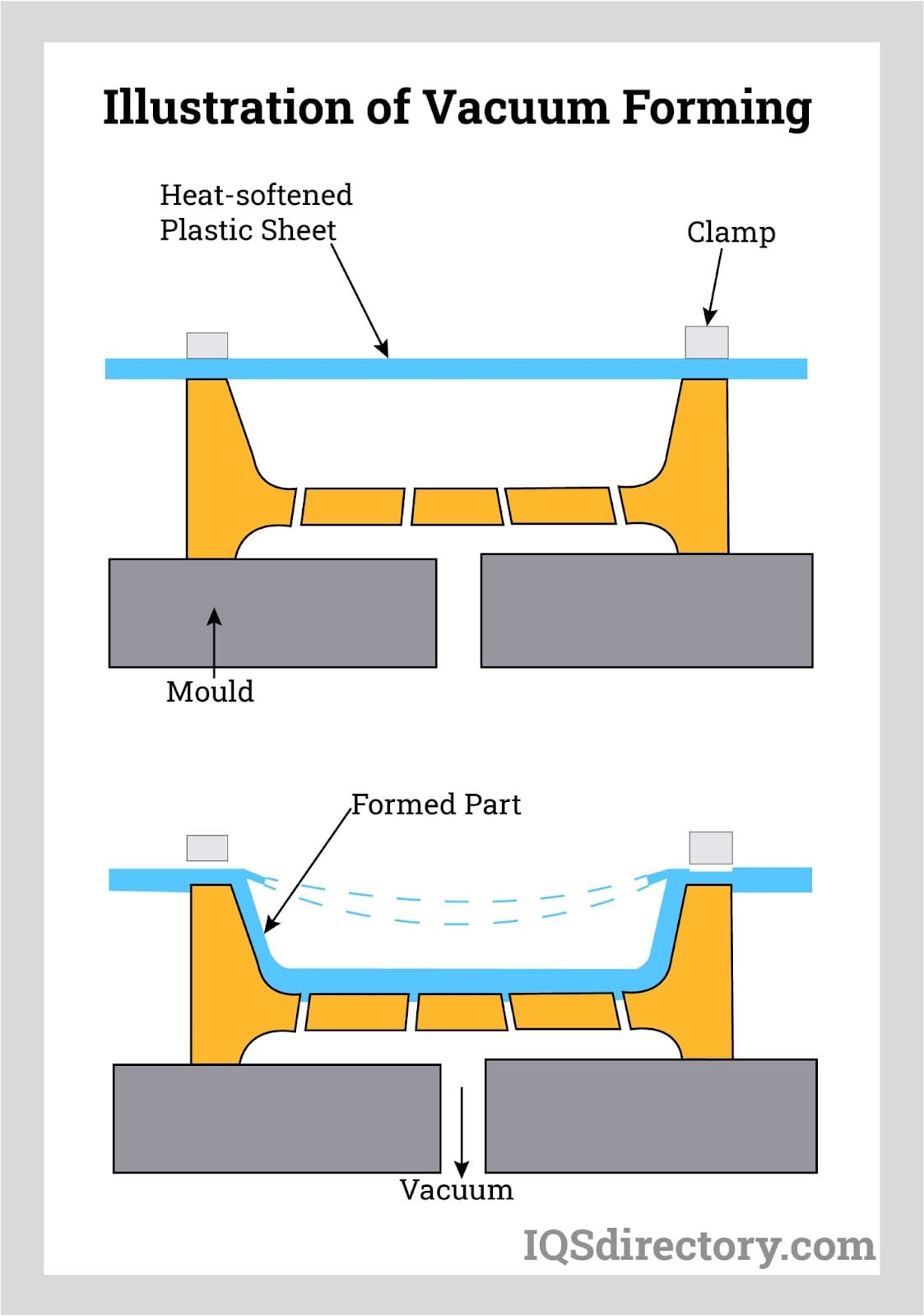

The first step involves forming the actual blisters. There are two primary manufacturing methods:

- Cold forming: A (PVC) film laminate is pressed into a mold without the use of heat. This process is ideal for products sensitive to heat and provides superior protection against moisture and oxygen. The resulting blisters are typically opaque, which can be a limitation for product visibility.

- Thermoforming: The plastic film is heated over a mold, allowing it to be stretched and shaped into the desired cavity form. Thermoformed blisters are usually made from PVC or PET and offer excellent product visibility and design flexibility.

2. Product Loading

Once the blister cavities are formed, the products are inserted into the compartments. At this stage, packaging lines check for compatibility between the product size, blister size, and batch requirements. Automation and precision are key here to ensure each item is placed correctly, especially for high-speed pharmaceutical packaging or retail packaging lines.

3. Sealing

The next stage is sealing, where the blister and the backing material are joined using heat and pressure. This creates a hermetic seal, protecting the product from external factors such as moisture, contaminants, and tampering. The type of backing—foil, paperboard, or film—affects the seal’s strength and barrier properties.

4. Coding and Traceability

Coding is critical for compliance and traceability in the pharmaceutical and food industries. Important information such as batch numbers, expiration dates, and manufacturing dates are printed or embossed onto the blister packs. This step ensures regulatory compliance and helps with recall management and consumer safety.

5. Perforation and Cutting

The final stage involves perforating and cutting the blister packs into individual units or strips. Perforation allows consumers to easily separate doses or servings, enhancing usability and convenience. The finished packs are then inspected for quality assurance.

Applications of Blister Packaging Across Industries

Blister packaging offers a versatile solution for a wide range of applications. Its unique properties make it a preferred choice for industries seeking tamper-evident, protective, and visually appealing packaging. Explore common and emerging use cases below:

- Pharmaceutical Packaging: Blister packs are the standard for oral solid dose pharmaceuticals such as tablets, capsules, and lozenges. They provide unit-dose packaging, improve patient adherence, and offer child-resistance and senior-friendliness with custom designs. Many over-the-counter and prescription drugs rely on blister packs for shelf stability and compliance labeling.

- Medical Devices and Diagnostics: Single-use medical devices, test kits, syringes, and diagnostic strips are often packaged in blisters to maintain sterility and ensure traceability. Blister packaging supports critical regulations in the healthcare sector.

- Consumer Goods: Items such as batteries, small electronics, memory cards, USB drives, and accessories are commonly packaged in blisters. This method prevents theft, enhances shelf appeal, and allows for the inclusion of product information, branding, and instructions.

- Food Packaging: Certain foods, candies, chewing gum, and supplements are packed in blister packs to maintain freshness, prevent contamination, and allow for portion control.

- Retail and Hardware: Toys, tools, fasteners, razor blades, stationery, and similar products are frequently packaged in blisters for easy display, tamper evidence, and theft deterrence.

Blister packaging is valued for its ability to:

- Keep products dry and provide water resistance, as the thermoformed polymer protects contents from moisture, vapor, or liquids. The level of water resistance depends on the backing material used—aluminum foil offers high resistance, while paper-based lids are less effective.

- Offer an excellent barrier to oxygen and moisture, significantly extending shelf life for pharmaceuticals and perishable goods.

- Protect goods from UV light using metallized PVC or specialty films, thus preserving product potency and quality.

- Provide tamper evidence, as blister packs cannot be easily resealed once opened. This enhances product safety and consumer confidence.

- Enhance product visibility, as clear blisters allow customers to view items directly before purchase, which is especially useful in retail environments.

Advantages of Using Blister Packaging

When evaluating packaging solutions, it's crucial to consider the unique benefits of blister packaging. Here are the most significant advantages:

- Portability: Compared to bottled medications or boxed products, blister packs are lightweight, compact, and easy to carry. Consumers can take only the required doses or portions, which is convenient for travel, daily use, or sample distribution.

- Protection: Blister packaging maximizes product safety through fully automated, contamination-free processes. The strong seal makes the packaging waterproof, moisture-proof, dust-proof, and rust-proof, extending shelf life and reducing waste. Tamper-evident features provide reassurance to both retailers and consumers.

- Variety: There are multiple types of blister packaging, including clamshell packaging, wallet packs, and traditional push-through blisters. This variety allows businesses to select the optimal packaging for their product type, branding, and regulatory needs. Custom shapes and sizes can be designed for enhanced product differentiation.

- Marketing Potential: The rear card or backing of a blister package is an excellent space for marketing, branding, and informational content. Manufacturers can print instructions, promotions, and regulatory data, making the packaging both educational and visually appealing.

- Serving Size and Dosing Accuracy: Blister packaging is perfect for food and medication storage as it enables precise portion control. Each blister unit can contain a single serving or dose, supporting accurate consumption, reducing dosing errors, and improving compliance—critical factors in healthcare and nutrition applications.

- Cost Efficiency and Sustainability: Blister packs use less material than bottles or jars, reducing shipping costs and storage space. Advances in recyclable and biodegradable materials are making blister packaging more sustainable, aligning with environmental goals and regulations.

Limitations of Blister Packaging

While blister packaging offers many benefits, it's important to understand its potential drawbacks when researching or selecting packaging solutions:

- Production can be time-consuming and may require specialized equipment, leading to higher initial manufacturing costs compared to some alternative packaging formats.

- Blister packs are sometimes difficult to open, particularly for seniors or people with limited dexterity. This can be a consideration for products targeting elderly consumers or requiring frequent access.

- Not all products are suitable for blister packaging—bulky, heavy, or odd-shaped items may require different packaging solutions.

- Some blister materials, such as PVC, have environmental drawbacks. However, eco-friendly alternatives like PET or compostable films are becoming more popular.

Types of Blister Packaging Solutions

Blister packaging comes in several forms, each tailored to specific product requirements and industry needs. Common types include:

- Face Seal Blister Packs: The blister is heat-sealed to a card, covering only the product area. This is cost-effective and used widely for retail display.

- Full Face Seal Blisters: The plastic covers the entire card face, providing greater protection and security.

- Trapped Blisters: The blister is trapped between two cards, offering extra tamper resistance and a premium appearance.

- Clamshell Packaging: A hinged, self-closing blister that forms a protective shell around the product, ideal for heavier or higher-value items.

- Wallet Packs: Blister packs designed for patient adherence, often containing multiple doses and printed with dosing calendars and instructions.

Blister Packaging Materials: Choosing the Right Option

Material selection is a critical decision factor in blister packaging design. The main materials include:

- PVC (Polyvinyl Chloride): Most common, affordable, and easily thermoformed but less eco-friendly.

- PVDC (Polyvinylidene Chloride): Offers enhanced moisture and oxygen barrier properties, commonly used in pharmaceutical blister packs.

- PET (Polyethylene Terephthalate): Recyclable and clearer than PVC, increasingly popular for sustainable packaging.

- Aluminum Foil: Used primarily as a backing for pharmaceutical blisters, providing an excellent moisture, gas, and light barrier.

- Paperboard: Often used for the card backing in retail blisters, enabling high-quality printing and branding.

When evaluating which material to use, consider factors such as product sensitivity, shelf life requirements, regulatory compliance, environmental impact, and branding opportunities.

How to Select the Best Blister Packaging Partner

Choosing the right blister packaging supplier is crucial for ensuring quality, compliance, and cost efficiency. Here are steps and decision factors to guide your sourcing process:

- Define Your Needs: Identify your product’s dimensions, sensitivity, shelf life, branding requirements, and regulatory environment.

- Assess Supplier Capabilities: Evaluate if the supplier offers custom design, prototyping, high-speed production, and compliance with industry standards (such as FDA, GMP, or ISO certifications).

- Review Materials Offered: Ensure the supplier provides a range of material options, including sustainable alternatives, and can advise on best fit for your application.

- Compare Costs and Lead Times: Request quotes from multiple packaging companies and compare not only price but also turnaround, minimum order quantities, and scalability.

- Check References and Track Record: Look for suppliers with proven experience in your industry and positive client testimonials.

- Request Samples and Prototypes: Always test sample packaging for fit, functionality, and visual appeal before committing to large production runs.

Frequently Asked Questions About Blister Packaging

- What are the main benefits of using blister packaging for pharmaceuticals? Blister packaging offers unit-dose control, tamper evidence, product protection, and compliance support, making it ideal for medication packaging.

- How do I choose between thermoforming and cold forming for my product? Consider product sensitivity to heat, barrier requirements, and whether clear visibility is needed. Thermoforming suits visible retail items, while cold forming gives superior barrier protection for sensitive medicines.

- Can blister packaging be recycled? Many modern blisters use recyclable PET or eco-friendly materials. Always check local recycling guidelines and ask suppliers about sustainable options.

- What industries use blister packaging? Pharmaceuticals, food, consumer electronics, hardware, retail, and medical devices are the leading sectors using blister packs.

- How can I ensure my blister packaging is child-resistant? Work with suppliers who offer child-resistant and senior-friendly features, such as push-through resistance, peelable lidding, and compliance with regulatory standards.

Choosing the Proper Blister Packaging Company

To make sure you have the most beneficial outcome when purchasing Blister Packaging from a Blister Packaging Supplier, it is important to compare at least 5 Companies using our list of Blister Packaging suppliers. Each Blister Packaging Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Blister Packaging company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Blister Packaging businesses with the same message.

Ready to find the best blister packaging supplier for your needs? Browse our curated list of trusted blister packaging companies and request quotes to compare solutions tailored to your industry and product specifications.

Explore More About Blister Packaging

- What’s the difference between blister and clamshell packaging?

- How is pharmaceutical packaging evolving with new regulations and sustainability initiatives?

- What are the best packaging options for food and supplements?

Conclusion: Is Blister Packaging Right for Your Product?

Blister packaging stands out for its blend of product protection, tamper evidence, marketing potential, and consumer convenience. Whether you’re in pharmaceuticals, consumer goods, food, or electronics, blister packs offer unmatched versatility and efficiency. However, choosing the optimal blister packaging solution requires careful consideration of your product’s characteristics, regulatory needs, and sustainability goals. With the right partner and materials, blister packaging can enhance your product’s value, shelf presence, and customer satisfaction.

Have more questions about blister packaging, or need expert guidance? Contact our packaging experts today for a tailored consultation and discover how advanced blister packaging can optimize your product strategy.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services