With our longstanding history of being at the top of the market we are committed to bringing our customers only the best in quality, service and reliability.

Founded in 1987, Brisar Delvco Industries, Inc., is a leader in turn-key Contract Packaging Solutions. We provide a broad range of in-house services including blister packaging, blister carding, medical device packaging, pouching dietary supplements, OTC drugs, overwrapping, Direct Mail promotional packaging, auto-cartoning, along with other packaging processes. All under one umbrella in a...

At Akers Packaging Service Group, we take pride in delivering comprehensive packaging solutions that go far beyond simply supplying materials. Our strength lies in contract packaging, where we bring together decades of expertise, state-of-the-art facilities, and a dedicated team to manage packaging projects from start to finish.

Based in California, Teamwork Packaging specializes in all aspects of turnkey packaging. We provide innovative packaging solutions in response to the changing needs of the packaging industry. Our custom packaging displays will meet and exceed your specific packaging needs. Some of our services include auto-bagging, cello wrapping, coding, shrink wrapping, sleeve bundling and more. Call us today!

At RCS Empowers, Inc., we take pride in providing high-quality contract packaging services that help our partners streamline production and meet their customers’ needs efficiently. We understand that every packaging project is unique, which is why we offer flexible solutions designed to handle a wide range of products, from consumer goods to industrial materials.

More Pharmaceutical Packaging Companies

Pharmaceutical packaging refers to the specialized wrapping, enclosing, and labeling of medicinal products to guarantee their safety, efficacy, and integrity from the point of manufacture through distribution to the end-user. In the modern pharmaceutical industry, packaging is not just a means of containment, but a critical part of the medication delivery process. It serves to shield pharmaceutical products from environmental factors, prevent misuse or tampering, support regulatory compliance, and reinforce brand trust. In fact, the packaging of pharmaceutical products is nearly as important as the medicines and devices themselves, ensuring that every dose reaches the patient safely and with its intended potency.

The pharmaceutical packaging industry employs a multi-layered approach to protect medicinal products at every stage. All three levels of packaging are used:

- Primary packaging—the immediate container that directly holds the drug or medical device, such as blister packs, bottles, or vials.

- Secondary packaging—encloses the primary containers, typically as cartons or boxes for grouped products.

- Tertiary packaging—bulk packaging used for shipping and logistics, such as assembling boxes onto pallets.

With advances in pharmaceutical packaging technology, solutions like tamper-evident, tamper-resistant, and child-resistant packaging have become industry standards. Innovations such as anti-counterfeiting measures, serialization, and smart packaging with digital tracking are now widely adopted to ensure patient safety, regulatory compliance, and supply chain transparency. Preserving product shelf-life, maintaining sterility, and supporting patient adherence are all critical objectives met by modern packaging solutions.

Characteristics of Good Pharmaceutical Packaging

High-quality pharmaceutical packaging must meet stringent industry standards and regulatory requirements. When evaluating or designing pharmaceutical packaging materials and solutions, consider the following essential characteristics:

- Protection from environmental hazards—Effective packaging shields pharmaceuticals from microorganisms, humidity, oxygen, temperature fluctuations, and light exposure. This is crucial for maintaining drug stability and shelf-life, especially for sensitive biologics, injectables, and oral solid doses.

- Physical protection—Packaging must guard against mechanical shocks, vibration, drops, or compression during transportation, storage, and handling. Robust packaging design ensures product integrity throughout the supply chain.

- Content retention and containment—Good packaging prevents leakage, evaporation, or contamination of its contents. This ensures patients receive accurate doses and mitigates risks of product loss.

- Clear labeling and traceability—Pharmaceutical packaging should display essential product information: drug name, strength, dosage instructions, batch number, expiration date, manufacturer details, and regulatory symbols. This aids in identification, traceability, and patient safety.

- Ease of use and accessibility—User-friendly packaging design allows patients, caregivers, and healthcare professionals to access the medication easily while deterring unauthorized access (for example, via child-resistant closures or tamper-evident features).

- Material compatibility and inertness—Packaging materials must not react chemically or physically with the pharmaceutical product. Incompatibility could compromise drug quality and safety.

- Environmental sustainability—Modern pharmaceutical packaging solutions increasingly incorporate recyclable, biodegradable, or eco-friendly materials to align with sustainability initiatives and regulatory trends.

- Aesthetic appeal and branding—Attractive, well-designed packaging can enhance brand recognition and consumer trust, while also conveying professionalism and quality.

Types of Pharmaceutical Packaging

Pharmaceutical packaging is highly regulated and tailored to the specific requirements of each medication or medical device. Understanding the main types of packaging used in the industry can help you select the best solution for your product and market.

There are seven major types of pharmaceutical packaging, each serving unique use cases and offering distinct benefits:

Vials

Pharmaceutical vials are small containers—typically made of glass (borosilicate or soda-lime) or high-grade plastics—used to store a range of pharmaceutical forms, including injectable liquids, powders, and capsules. Vials are widely used in vaccine packaging, biologic drug containment, and specialty medications. They feature various sealing options, such as rubber stoppers with aluminum crimp seals, screw caps, or flip-off tops, to maintain sterility and prevent contamination.

- Common applications: Injectable drugs, vaccines, lyophilized powders, diagnostic reagents.

- Buyer considerations: Material compatibility, sterility requirements, tamper evidence, regulatory compliance.

Ampoules (Ampules)

Ampoules are sealed, single-dose containers—usually made from glass—used for the preservation of liquid pharmaceuticals. The tight seal is achieved by melting the glass neck using a flame, ensuring a hermetic barrier against external contaminants. To access the dose, the user snaps off the neck. Ampoules are preferred for highly sensitive or unstable drugs that require an air-tight, inert environment.

- Common applications: Injectable medications, anesthetics, biologics, vaccines.

- Advantages: Absolute sterility, tamper-proof, ideal for single-use applications.

Blister Packs

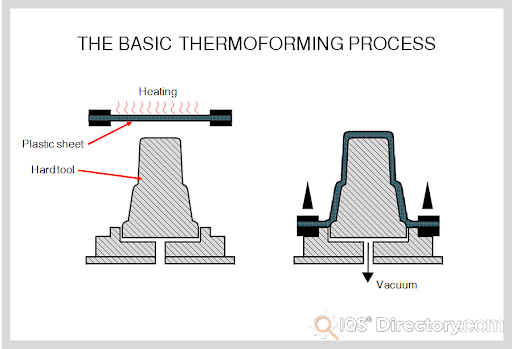

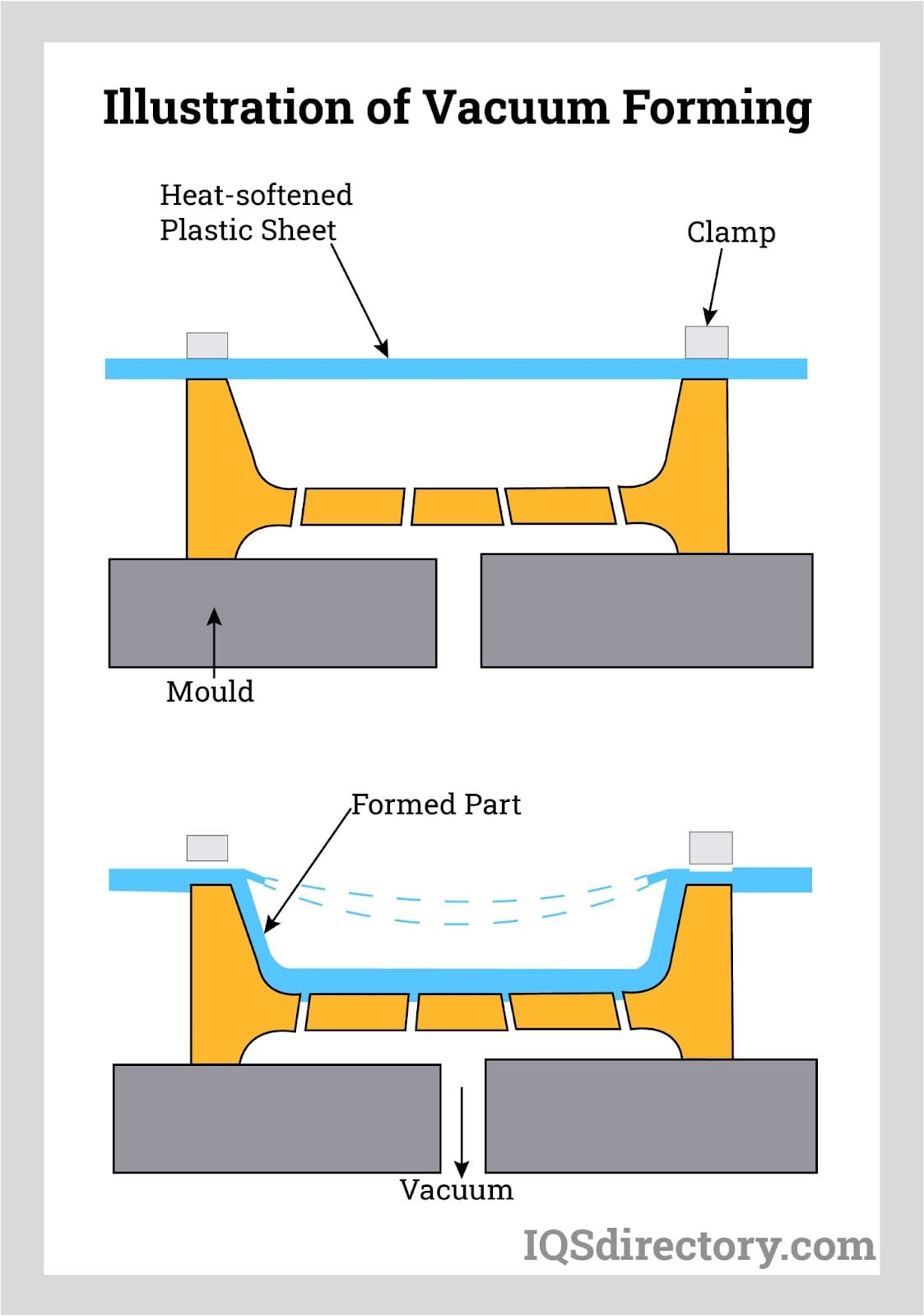

Blister packaging is one of the most popular forms of pharmaceutical packaging, especially for oral solid doses. A blister pack consists of pre-formed plastic cavities—often made from PVC, PVDC, or thermoformed aluminum—sealed with a backing of aluminum foil, paperboard, or film. Blister packs offer protection from moisture, air, and light, while facilitating dose accuracy and tamper evidence.

- Common applications: Tablets, capsules, lozenges, diagnostic strips.

- Benefits: Enhanced patient compliance, unit-dose dispensing, child resistance, and clear visibility of contents.

- Decision factors: Material barrier properties, required shelf-life, market regulations.

Sterile Packaging

Sterile pharmaceutical packaging is essential for products that must remain free from microbial contamination. This category includes materials and formats such as sterile pouches, trays, and wraps, often coated with medical-grade plastic films or laminates. Sterile packaging is vital for injectables, surgical devices, and medical implants, and must meet stringent validation and regulatory standards (e.g., USP, ISO).

- Applications: IV solutions, surgical kits, wound care products, diagnostic reagents.

- Key features: Hermetic sealing, validated sterilization methods (gamma irradiation, ethylene oxide, steam).

Sachet Packaging

Sachets are single-use, flexible pouches—typically made from laminated film, paper, or foil—used to package powdered, granulated, or liquid pharmaceuticals. Sachets are perforated for easy opening, ensuring accurate dosing and minimizing waste. Their small, portable format is favored for over-the-counter medications, dietary supplements, and sample packaging.

- Applications: Electrolyte powders, oral suspensions, sample medications, topical creams.

- Buyer questions: What are the optimal materials for product compatibility and shelf-life?

Metal Packaging

Metal packaging for pharmaceuticals dates back to the early 20th century and is still used for certain applications today. Metal containers, such as aluminum tubes, tins, and cans, offer excellent protection against light and physical damage. However, careful consideration must be given to the potential reactivity of metals with specific drug formulations. Modern advancements in coatings and linings help mitigate compatibility concerns.

- Applications: Ointments, semi-solids, topical creams, light-sensitive products.

- Benefits: Opaque protection, excellent barrier properties, recyclability.

Bottles

Pharmaceutical bottles are among the most versatile and widely used packaging formats. Available in plastic (HDPE, PET, PP) or glass, bottles are used for liquids, solids, and powders. Color variations (amber, cobalt, opaque) provide additional protection from UV and visible light, while tamper-evident and child-resistant closures enhance safety.

- Applications: Syrups, oral suspensions, tablets, capsules, topical solutions.

- Decision factors: Material selection, closure type, label compatibility, regulatory compliance.

Types of Pharmaceutical Packaging Equipment

The pharmaceutical packaging process relies on advanced machinery to ensure product safety, efficiency, and quality control. The selection of packaging equipment directly impacts production throughput, automation levels, regulatory compliance, and product integrity. Below are some of the most commonly used pharmaceutical packaging machines and their roles in the industry:

Blister Packing Machine

Blister packaging machines form, fill, and seal blister packs used to contain tablets, capsules, vials, syringes, and ampoules. These machines automate the thermoforming or cold-forming of packaging films, product placement, sealing, and cutting into individual packs. Modern machines offer features such as vision inspection, serialization, and high-speed operation, making them indispensable in large-scale pharmaceutical production.

- Benefits: High output, precise dose control, tamper evidence, compliance with GMP and FDA standards.

- Use cases: Batch production of oral solids, clinical trial packaging, over-the-counter medications.

Strip Packing Machine

Strip packaging machines are designed for packaging tablets, capsules, lozenges, and similar products between two layers of heat-sealable materials such as aluminum foil, cellophane, or polyethylene. These machines offer high-speed operation and precise temperature control, ensuring product protection and consistent sealing quality.

- Applications: Unit-dose packaging, pediatric medications, sample packs.

- Advantages: Moisture resistance, tamper evidence, portability.

Effervescent Packing Machine

Effervescent tablet packing machines are engineered to package fragile, moisture-sensitive tablets—such as vitamin C or electrolyte effervescent tablets—into protective tubes with tight-fitting lids. These machines ensure gentle handling, accurate product counting, and secure sealing to maintain product integrity and shelf-life.

- User query: How do effervescent packing machines support moisture control and product integrity?

Syrup Powder Filler Machine

Syrup powder filling machines dispense measured quantities of dry syrup powders into bottles or containers. These machines are equipped with auger filling, vibration, and dust extraction systems to ensure precise dosing and prevent cross-contamination.

- Applications: Pediatric syrups, antibiotics, dietary supplements.

- Benefits: High accuracy, reduced wastage, compliance with cGMP.

Cartoning Machine

Cartoning machines automate the process of placing primary packaged products—such as bottles, vials, syringes, blister packs—into folding cartons or boxes. This equipment ensures products are securely packed, tamper-evident, and ready for distribution. Modern cartoning machines integrate labeling, leaflet insertion, and serialization for regulatory compliance.

- Use cases: Multipack cartons, hospital supply kits, retail-ready packaging.

- Decision factor: What automation level best suits your production scale?

Liquid-Filling Machine

Liquid-filling machines are designed for accurately dispensing pharmaceutical liquids—such as syrups, suspensions, injectables—into containers like vials, bottles, or IV bags. These machines are available in semi-automatic and fully automatic variants, and feature precise dosing, anti-drip mechanisms, and sterile filling environments to prevent contamination.

- Applications: Cough syrups, eye drops, biologicals, IV fluids.

- Key features: High throughput, programmable dosing, compatibility with a wide range of viscosities.

Other essential pharmaceutical packaging equipment includes labeling machines, capping machines, induction sealing machines, leak testers, and vision inspection systems. Selecting the right mix of machinery is vital for regulatory compliance, quality assurance, and operational efficiency.

Importance of Pharmaceutical Packaging

Why is pharmaceutical packaging critical in the healthcare industry? The packaging of drugs and medical devices plays a pivotal role in:

- Product protection—Packaging safeguards medications from contaminants, environmental hazards, and accidental damage, ensuring patient safety and drug efficacy.

- Preserving efficacy and potency—Proper packaging prevents degradation from exposure to light, moisture, oxygen, or temperature extremes, maintaining the intended therapeutic effect until the end of shelf-life.

- Supporting regulatory compliance—Pharmaceutical packaging must display essential information and meet labeling, serialization, and anti-counterfeiting requirements set by agencies such as the FDA, EMA, and WHO.

- Facilitating patient adherence—Innovative packaging designs make it easier for patients to take medication as prescribed, improving outcomes. Unit-dose packaging, calendar packs, and easy-to-open formats are examples.

- Preventing unauthorized access—Child-resistant closures and tamper-evident seals reduce the risk of accidental ingestion or tampering.

- Supporting branding and differentiation—Attractive, consistent packaging reinforces brand identity and helps consumers and healthcare professionals identify the product quickly and accurately.

- Logistics and supply chain efficiency—Well-designed packaging optimizes space, reduces shipping costs, and simplifies inventory management.

- Enabling traceability and serialization—Modern packaging incorporates unique identifiers (barcodes, QR codes, RFID tags) to support track-and-trace initiatives, combat counterfeiting, and facilitate recalls.

Key Considerations When Choosing Pharmaceutical Packaging Suppliers

Finding the right pharmaceutical packaging manufacturer or supplier is a crucial decision for pharmaceutical companies, contract development and manufacturing organizations (CDMOs), and healthcare brands. Here are some actionable tips and decision points to guide your sourcing process:

- Compliance and certifications—Does the supplier hold ISO, cGMP, FDA, or other relevant certifications? Are their facilities regularly inspected and audited?

- Material expertise—Does the manufacturer offer a range of materials suitable for your formulation (e.g., glass, medical-grade plastics, barrier films, aluminum)?

- Customization capabilities—Can the supplier provide custom packaging solutions tailored to your product’s size, dosage, and regulatory needs?

- Innovation and technology—Does the supplier invest in R&D, smart packaging, or anti-counterfeiting technologies?

- Supply chain reliability—What is their track record for on-time delivery, order accuracy, and support during market fluctuations?

- Quality assurance—How does the supplier perform quality control, batch testing, and validation?

- Cost efficiency—Are their solutions competitively priced? Can they support both small-batch and high-volume production?

- Sustainability practices—Do they offer recyclable, biodegradable, or eco-friendly packaging options to align with your corporate sustainability goals?

To ensure the best outcome when purchasing pharmaceutical packaging, it’s recommended to:

- Compare at least 4 or 5 suppliers using a trusted pharmaceutical packaging directory.

- Review each manufacturer’s business profile, expertise, certifications, and capabilities.

- Use direct contact forms or RFQ tools to request quotes and detailed information tailored to your needs.

- Evaluate sample products and request references to verify quality and service levels.

- Assess their website for evidence of regulatory compliance, innovation, and customer support.

Ready to find the right supplier? Ask yourself: What are your most important priorities—speed to market, regulatory compliance, or innovative packaging features? Use our directory to streamline your search and connect with pre-vetted pharmaceutical packaging companies.

Emerging Trends in Pharmaceutical Packaging

The pharmaceutical sector is rapidly evolving, and packaging trends are adapting to new challenges and opportunities. Staying up to date with these trends can help your organization maintain compliance, enhance product safety, and capitalize on market differentiation:

- Smart packaging—Integration of QR codes, NFC chips, sensors, and digital authentication enables patient engagement, product verification, and real-time supply chain monitoring.

- Personalized and connected packaging—Customizable packaging supports personalized medicine and adherence programs, while connected devices remind patients to take their medication.

- Eco-friendly materials—Growing demand for recyclable, compostable, and biodegradable packaging materials supports environmental stewardship and regulatory compliance.

- Anti-counterfeiting technologies—Features such as holograms, tamper-evident seals, and serialization help combat the global threat of counterfeit drugs.

- Regulatory harmonization—Globalization is driving the need for harmonized packaging and labeling standards to simplify compliance across multiple markets.

Are you seeking ways to future-proof your pharmaceutical packaging? Explore how smart packaging and sustainability can give your brand a competitive edge in today’s marketplace.

Frequently Asked Questions About Pharmaceutical Packaging

- What is the difference between primary, secondary, and tertiary pharmaceutical packaging?

Primary packaging directly contacts the drug (e.g., vial or blister pack), secondary packaging groups primary containers (e.g., cartons), and tertiary packaging bundles products for shipping (e.g., pallets). - How do regulations impact pharmaceutical packaging design?

Regulations dictate material selection, labeling, tamper-evidence, child-resistance, and serialization, ensuring product safety and traceability. - What materials are commonly used in pharmaceutical packaging?

Glass, medical-grade plastics (HDPE, PET, PVC), aluminum foil, paperboard, and composite laminates are frequently used, selected based on compatibility, barrier properties, and regulatory standards. - How can pharmaceutical packaging improve patient adherence?

User-friendly designs, clear labeling, unit-dose packs, and reminder-enabled smart packages all support correct and timely medication use. - What should I look for in a pharmaceutical packaging supplier?

Prioritize compliance, expertise, innovation, quality assurance, and supply reliability. Ask about customization, sustainability, and technology integration.

Conclusion: Empower Your Brand with Best-in-Class Pharmaceutical Packaging

Choosing the right pharmaceutical packaging solutions is fundamental to protecting patients, ensuring regulatory compliance, and standing out in a competitive market. Whether you need primary packaging for sensitive biologics, child-resistant secondary packaging, or sustainable tertiary solutions for global distribution, partnering with an experienced, innovative supplier is essential. Use our comprehensive directory and evaluation tools to connect with leading pharmaceutical packaging manufacturers and make informed, future-ready decisions for your business.

Start your pharmaceutical packaging supplier search now—find partners that match your product needs, compliance requirements, and innovation goals with confidence.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

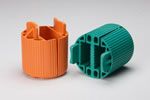

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services