With our longstanding history of being at the top of the market we are committed to bringing our customers only the best in quality, service and reliability.

Founded in 1987, Brisar Delvco Industries, Inc., is a leader in turn-key Contract Packaging Solutions. We provide a broad range of in-house services including blister packaging, blister carding, medical device packaging, pouching dietary supplements, OTC drugs, overwrapping, Direct Mail promotional packaging, auto-cartoning, along with other packaging processes. All under one umbrella in a...

At Akers Packaging Service Group, we take pride in delivering comprehensive packaging solutions that go far beyond simply supplying materials. Our strength lies in contract packaging, where we bring together decades of expertise, state-of-the-art facilities, and a dedicated team to manage packaging projects from start to finish.

Based in California, Teamwork Packaging specializes in all aspects of turnkey packaging. We provide innovative packaging solutions in response to the changing needs of the packaging industry. Our custom packaging displays will meet and exceed your specific packaging needs. Some of our services include auto-bagging, cello wrapping, coding, shrink wrapping, sleeve bundling and more. Call us today!

At RCS Empowers, Inc., we take pride in providing high-quality contract packaging services that help our partners streamline production and meet their customers’ needs efficiently. We understand that every packaging project is unique, which is why we offer flexible solutions designed to handle a wide range of products, from consumer goods to industrial materials.

More Packaging Design Companies

Packaging design is a strategic process that merges the concepts and visualization of ideas, colors, and imagery to create functional, attractive, and protective solutions for products. Effective packaging design is the result of a creative collaboration that includes illustration, structural engineering, size optimization, and typography. Whether you’re launching a new product or redesigning an existing one, thoughtful packaging design is essential for market success and brand differentiation.

Packaging is not just about wrapping products—it's a comprehensive process that protects finished goods from mishandling, damage, and environmental exposure during transportation, storage, and display. Product packaging serves as a brand ambassador, communicates critical information, and drives consumer purchasing decisions at the point of sale. In the fiercely competitive retail landscape, packaging design influences shelf appeal, facilitates logistics, and extends a product’s lifespan while maintaining cleanliness and presentability. The right packaging design depends on factors such as product type, transportation method, duration of distribution, and even the geographic region in which the product will be sold.

What is Packaging Design? Understanding the Essentials

Packaging design is the art and science of enclosing products in containers that safeguard their integrity, enhance their visual appeal, and provide essential information to consumers. Beyond aesthetics, professional packaging design incorporates elements of material science, user experience, branding, and regulatory compliance. The choice of packaging can dictate how a product is perceived, its convenience for the end-user, and its suitability for various channels such as e-commerce, retail, and wholesale distribution.

Are you looking for the best way to make your product stand out on the shelf or online? Do you need packaging that balances protection, sustainability, and cost-effectiveness? Explore the latest trends in custom packaging design, eco-friendly packaging solutions, and innovative packaging materials to discover what will work best for your unique needs.

Characteristics of Good Packaging

Good product packaging delivers much more than attractive looks. The core characteristics of effective packaging design include:

- Clear and accurate labeling: Provides crucial information such as nutritional values, ingredients, instructions, and regulatory compliance, supporting both consumer decision-making and legal requirements.

- User-friendly opening and reclosing: Especially important for consumables and products used over time, easy-open and resealable packaging enhances customer experience and product longevity.

- Optimized sizing: The size of the packaging is tailored to the product, reducing waste, minimizing shipping costs, and ensuring efficiency in storage and transport.

- Durability and protection: Quality packaging materials shield products from physical, chemical, and environmental hazards, reducing returns and improving customer satisfaction.

- Brand visibility: Effective packaging design elevates brand recognition and encourages impulse purchases by standing out on crowded shelves or in online listings.

- Sustainability: Increasingly, businesses and consumers are prioritizing recyclable, biodegradable, or reusable packaging to reduce environmental impact and meet regulatory expectations.

- Cost-effectiveness: Good packaging strikes a balance between functionality, aesthetics, and production costs, optimizing the supply chain and profitability.

Key Factors Affecting Packaging Design

What should you consider when designing packaging for your product? Several critical factors influence the design, selection, and implementation of effective packaging solutions:

- Purpose of packaging: Is the packaging intended for direct consumer interaction, logistics, or both? Consumer packaging prioritizes protection, branding, and safety, while logistical packaging focuses on efficiency, bulk handling, and cost reduction.

- Nature of the product: The packaging requirements for solids, liquids, perishables, fragile items, or hazardous materials differ significantly. For example, food packaging often requires barrier properties, while electronics need anti-static protection.

- Product sensitivity: Some products are vulnerable to light, temperature, moisture, or oxygen. Packaging solutions must be tailored with materials and designs that mitigate these risks (e.g., vacuum sealing, UV-resistant films).

- Distribution distance and conditions: Products traveling long distances or through harsh environments require enhanced protection, tamper-evident features, and secure sealing mechanisms.

- Material handling systems: Packaging must be compatible with manual, semi-automated, or fully automated handling and filling systems, influencing size and structure.

- Regulatory and industry standards: Compliance with international and regional packaging regulations (such as FDA, EU, or ISO standards) is critical for many industries, including food, pharmaceuticals, and cosmetics.

- Environmental impact: Choosing sustainable packaging materials and minimizing waste is a growing concern for both companies and consumers, shaping design decisions and supply chain practices.

Levels of Packaging Design: Primary, Secondary, Tertiary

Understanding the three levels of packaging design is fundamental for optimizing product protection, transport, and display. Each level serves a distinct purpose:

Primary Packaging

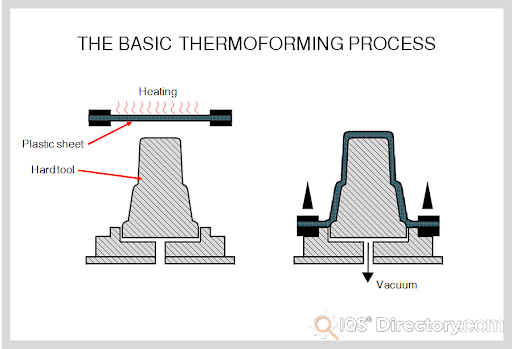

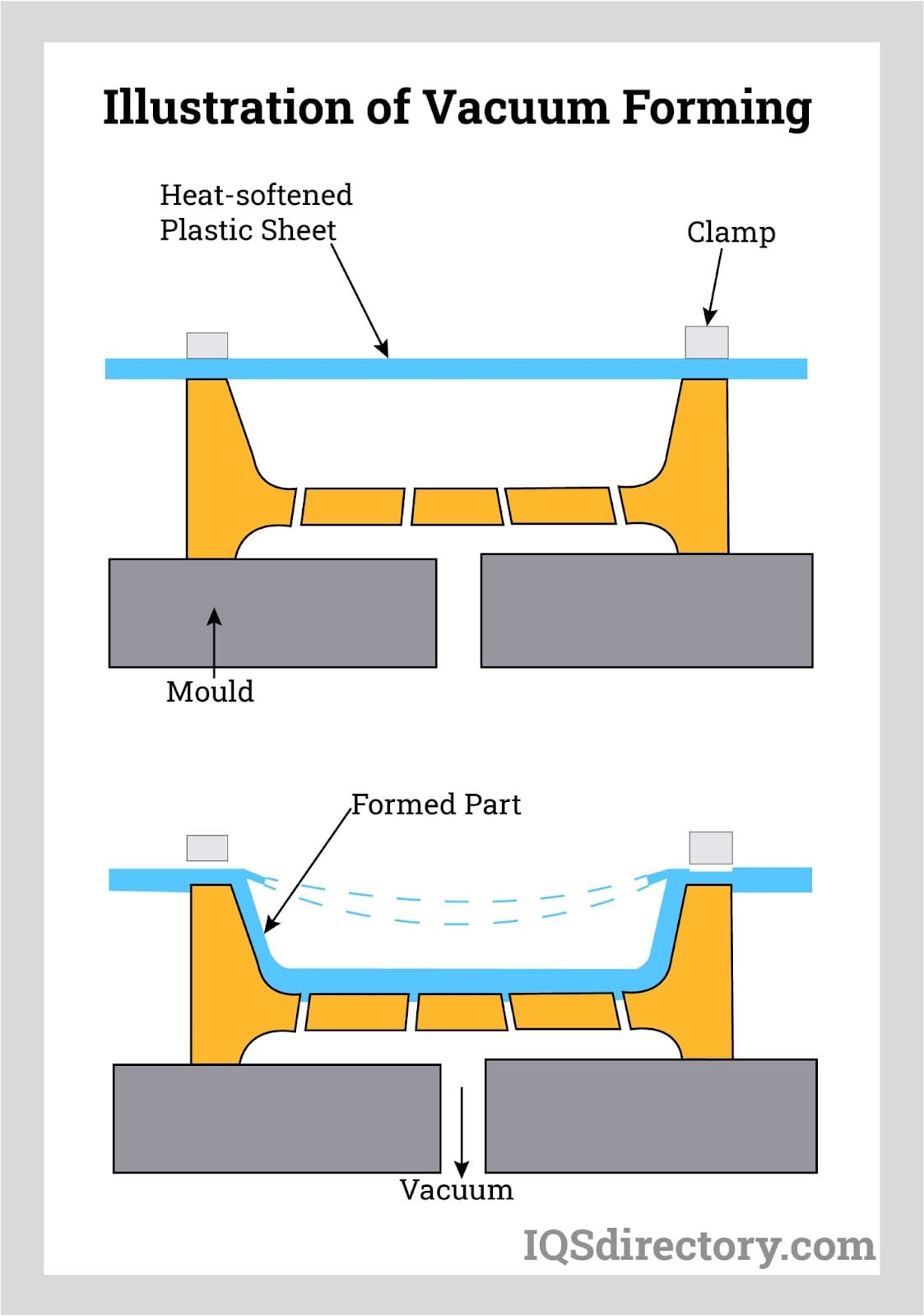

Primary packaging is the first layer of packaging in direct contact with the product itself—such as bottles, cans, wrappers, or blister packs. Its primary role is to protect the product from contamination, preserve freshness, and communicate essential information. Well-designed primary packaging can enhance user experience and reinforce brand identity. For example, a resealable zipper pouch for snacks or a tamper-evident seal on pharmaceuticals ensures both safety and convenience.

Secondary Packaging

Secondary packaging encases primary packages to create stock-keeping units (SKUs) for easier handling, identification, and display. Common examples include cartons, multipacks, and display boxes. Secondary packaging often serves as a bridge between transport needs and retail presentation, streamlining logistics while supporting merchandising strategies.

Tertiary Packaging

Tertiary packaging—also known as bulk, industrial, or transit packaging—groups multiple secondary packages for safe and efficient shipping. This level includes pallets, shrink-wrapped trays, and large shipping containers. Tertiary packaging is essential for warehouse storage, bulk transportation, and automated logistics operations, ensuring products reach their destination intact and organized.

Types of Packaging Materials: Choosing the Best for Your Product

What packaging material is best for your product? The right choice depends on the product’s physical properties, marketing goals, environmental considerations, and cost constraints. Here are the main types of packaging materials used across industries:

Paper and Carton Packaging

Paperboard and corrugated carton packaging are widely used for products ranging from food and beverages to electronics, toys, and apparel. Paper-based packaging is praised for its versatility, printability, and recyclability. Cartons can be custom-cut, folded, and printed to reflect brand identity and product information. Additionally, inner paper wraps or liners can provide extra protection against moisture or corrosion.

Packaging Films

Flexible packaging films—such as PVC, PE, and PP—are favored for their adaptability, transparency, and protective properties. These films can be engineered for specific functions: shrink film contracts with heat to tightly secure products, while stretch film maintains tension to bundle items without shrinkage. Common applications include shrink-wrapped multipacks, bubble wraps, vacuum pouches, and protective sleeves for electronics. Films may also incorporate anti-static, anti-fog, or barrier layers for specialized uses.

Packaging Foams

Foam packaging materials—such as polyethylene (PE) foam, polyurethane (PU) foam, and expanded polystyrene (EPS)—offer exceptional cushioning for fragile or sensitive products. Used extensively in furniture, glassware, electronics, medical devices, and industrial equipment, foam rolls, sheets, and inserts minimize vibration, shock, and breakage during shipping. Custom-molded foam solutions can be tailored to fit even the most complex product shapes.

Textile Packaging

Textile-based packaging uses natural fibers such as cotton, jute, flax, or synthetic materials to create reusable sacks, bags, and wraps. Particularly common in agricultural and food industries, textile packaging is valued for its breathability, strength, and eco-friendliness. These materials are ideal for grains, produce, and specialty goods requiring ventilation and moisture regulation.

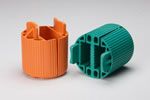

Plastic Packaging

Plastic packaging remains a dominant choice due to its strength, lightweight nature, and cost-effectiveness. Plastics such as PET, HDPE, LDPE, and polypropylene can be molded, blown, or extruded into bottles, jars, tubs, blister packs, and film wraps. Plastic packaging offers excellent barrier properties, flexibility in design, and extended shelf life, making it indispensable for food, pharmaceuticals, cosmetics, and household goods. Increasingly, innovations in biodegradable and recycled plastics are addressing environmental concerns.

Specialized Packaging Solutions: Meeting Unique Industry Needs

Different industries demand specialized packaging solutions tailored to their unique requirements:

- Food and Beverage Packaging: Emphasizes hygiene, tamper-evidence, freshness, and compliance with food safety regulations. Common solutions include vacuum-sealed pouches, aseptic cartons, and modified atmosphere packaging (MAP).

- Pharmaceutical Packaging: Requires child-resistant closures, tamper-proof seals, and accurate labeling for dosage and safety information. Blister packs, vials, and sterile containers are widely used.

- Cosmetic and Personal Care Packaging: Combines functionality with luxury branding through custom-shaped bottles, jars, and decorative finishes. Airless pumps and UV-blocking materials are popular choices.

- Electronics Packaging: Focuses on anti-static protection, cushioning, and secure sealing to prevent damage from shocks, moisture, or electromagnetic interference.

- Industrial and Automotive Packaging: Utilizes heavy-duty corrugated containers, foam inserts, and returnable transit packaging for large, heavy, or high-value components.

Benefits of Professional Packaging Design

Why invest in professional packaging design? The advantages span the entire product lifecycle and supply chain:

- Boosts shelf appeal: Eye-catching packaging increases visibility, attracts customers, and drives sales both in-store and online.

- Enhances brand identity: Unique packaging communicates your brand’s story, values, and quality promise, fostering customer loyalty.

- Protects product integrity: Robust packaging materials and construction reduce damage, spoilage, and returns, saving costs and reputation.

- Improves logistics efficiency: Well-designed packaging streamlines inventory management, transportation, and warehousing through stackability and space optimization.

- Supports regulatory compliance: Accurate labeling and packaging features safeguard consumer safety and avoid costly violations.

- Drives sustainability: Eco-friendly packaging designs reduce waste, meet consumer expectations, and enhance corporate responsibility initiatives.

- Facilitates customer experience: User-friendly features like resealable closures, ergonomic shapes, and easy-open mechanisms delight consumers and encourage repeat purchases.

How to Choose the Right Packaging Design Company

Wondering how to select the best packaging design supplier for your next project? Here’s a step-by-step guide to making an informed decision:

- Define your requirements: Identify your product’s needs, target audience, distribution channels, and goals for branding, sustainability, and cost.

- Research and compare suppliers: Use our Packaging Design directory to review profiles of top packaging design companies. Consider their expertise, industries served, capabilities (such as custom packaging, prototyping, or eco-friendly materials), and client testimonials.

- Request samples and proposals: Ask for physical samples or design mockups to evaluate quality, durability, and visual impact. Request detailed quotes that outline materials, lead times, and value-added services.

- Assess technology and innovation: Choose suppliers who leverage the latest in packaging design software, sustainable materials, and automation for efficiency and precision.

- Evaluate communication and support: A responsive supplier who collaborates transparently and offers design guidance is invaluable for a smooth project experience.

- Use our RFQ form: Streamline your search by contacting multiple Packaging Design companies at once with our simple request-for-quote tool.

Each Packaging Design Supplier has a comprehensive business profile page that highlights their areas of expertise, capabilities, and a contact form for direct communication. Use our patented website previewer to get a visual sense of each company's specialties before reaching out.

Frequently Asked Packaging Design Questions

- What are the latest trends in packaging design? Popular trends include minimalistic graphics, sustainable and reusable materials, smart packaging with QR codes or NFC, and personalized or limited-edition packaging for brand engagement.

- How do I choose sustainable packaging? Look for packaging made from recycled, biodegradable, or compostable materials. Consider the entire lifecycle impact and opportunities for reducing or reusing packaging components.

- Can packaging design impact my product’s market success? Absolutely. Studies show that packaging influences consumer perception, brand recall, and purchase decisions—making design a key driver of market differentiation and growth.

- What are the costs involved in custom packaging design? Costs vary based on materials, complexity, order volume, and value-added features such as embossing, foil stamping, or specialty coatings. Request detailed quotes and prototypes to understand total investment.

- How do I ensure my packaging meets industry regulations? Work with suppliers knowledgeable in regulatory standards for your industry, and verify that labeling, materials, and safety features are fully compliant.

- What’s the process for creating custom packaging? The typical steps include concept development, prototyping, material selection, design approval, production, and quality assurance.

Getting Started: Action Steps for Effective Packaging Design

- Contact a trusted packaging design supplier to discuss your product, branding, and distribution needs.

- Request a consultation or design audit to identify opportunities for improvement or cost savings in your current packaging.

- Explore innovative packaging options such as smart packaging, sustainable materials, or automated packaging solutions to stay ahead of market trends.

- Review case studies or success stories from similar industries to visualize the impact of effective packaging design on sales and customer satisfaction.

- Use our RFQ form to compare quotes and capabilities from multiple packaging design companies for the best results.

Conclusion: The Impact of Packaging Design on Business Success

In today's competitive landscape, packaging design is far more than a protective cover—it's a critical component of your product's identity, value proposition, and customer experience. By investing in professional packaging design, leveraging the right materials, and partnering with experienced suppliers, you can boost sales, reduce costs, enhance sustainability, and build lasting brand loyalty. Ready to elevate your packaging strategy? Explore top packaging design companies now or request a custom quote to get started on your next packaging solution.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services